Faygo union’s 6000BPH CSD bottle filling line with blowing filling packing machine is the ideal answer for anyone who requires to effectively fill carbonated drinks. This complete bottling machines has a blowing, filling, and packaging areas that works together to produce a fully-automated procedure that will streamline your manufacturing.

With the Faygo Union brand, you can be guaranteed of top-notch equipment which could supply you constant and dependable gratification. Each component in this filling line was manufactured and made to the best requirements to meet with the needs of the drink manufacturing industry.

The primary feature of this machine is its high-speed filling capabilities, helping you to refill up to 6,000 containers each hour. It's ideal for small-to-medium sized drink companies that are looking for a top level of production in their manufacturing line.

The blowing method in this product is very accurate. It creates top-quality PET that can meet the necessary requirements of the manufacturing of carbonated drinks. The filling procedure is also extremely efficient, having a high precision which means each container is filled with the perfect amount.

The packaging machine is similarly impressive, because it has an automatic packaging that guarantees your containers are packed seamlessly; ready to be delivered conveniently.

The Faygo Union’s 6000BPH CSD bottle filling line was designed with a display control system which helps it be super easy to operate. You can adjust the settings and monitor the machine’s performance with only a few details.

It's not only very efficient and dependable, but Faygo Union's CSD bottle filling line is additionally fashioned with security in mind. It's different security features will protect the operator and the machine during procedure

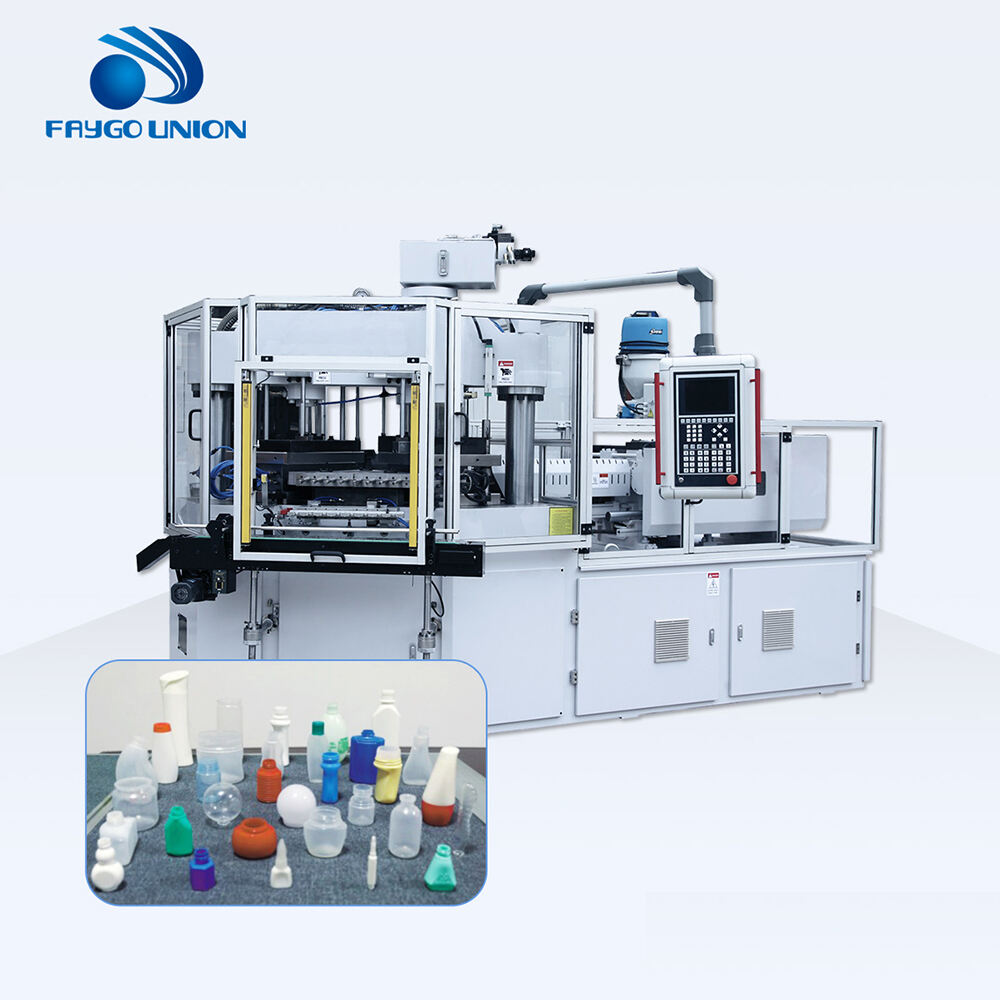

FULLY-AUTOMATIC LINEAR BOTTLE BLOWING MACHINE

1. SMART series of blowing machine fills the gaps in the domestic high-speed linear blowing machine. Currently, China linear single-mold speed still stays around 1200BPH, while international max single-mold has reached 1800BPH. High-speed linear blowing machines rely on imports

2. In view of this situation, Faygo Union Machinery developed China first high speed linear blowing machine: FG4. The single mold speed can reach 2000 BPH. FG4 has 4 cavities, production capacity is 8000BPH. It is developed completely independently, has our own intellectual property rights, and has obtained more than 13 national patents.

3. The machine is equipped with automatic perform loading and unloading system. The machine is applicable for all shapes of drinking water bottles. FG4 is composed of three modules: perform elevator, perform unscrambler and host machine

4. FG4 is completely new generation of linear machine, distinguished by its high speed, low power and low compressed air consumption, featured by the excellent structure design, small space occupation, less noise and excellent stability, meanwhile conforms to national beverage sanitary standards. It symbolizes the highest level of national linear blowing machine. It is the ideal bottle making equipment for beverage enterprises

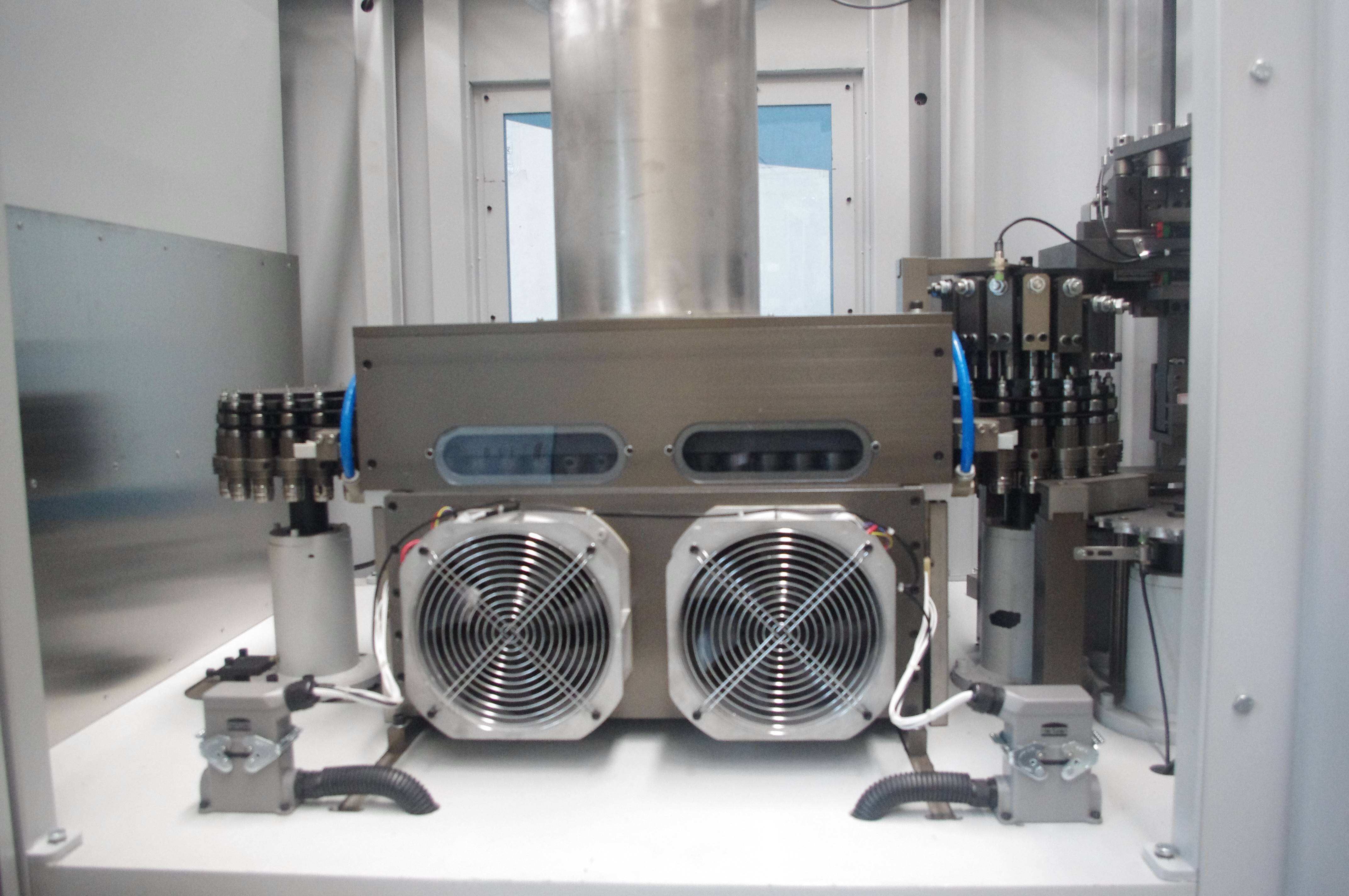

The unique cam linking system integrates mold-opening, mold-locking and bottom mold-elevating in one movement, equipped with high speed servo driving system which greatly shortens the blowing cycle and accelerates the speed

Equipped with remote monitoring system, engineers in China headquarter can check the data collected and sent by the PLC anytime with the mobile, feedback will be informed to the client' s site if something abnormal, give the machine 24 hours' baby care in the cradle

Heater distance in the heating oven is minimized to 38.1mm, compared with the conventional heating oven, it saves more than 30% electricity consumption

Equipped with the air cycling system and redundant heat discharge system, it ensures the constant temperature in the heating zone

The machine adopts modularized design concept to make it convenient and cost-saving for the maintenance and changing changeovers. To change mold only need 30 minutes

Type |

|

|

FG4 |

FG4F |

FG6 |

FG8 |

Mark |

|

Bottle

specification |

Mould number(piece) |

|

4 |

4 |

6 |

8 |

|

|

|

|

maxi volume (mL) |

|

2000 |

1500 |

2000 |

750 |

|

|

|

maxi height (mm) |

|

328 |

328 |

328 |

290 |

|

|

|

Round bottle max diameter (mm) |

|

105 |

105 |

105 |

75 |

|

|

|

Max capacity(BPH) |

|

6500-8000 |

4000-4500 |

9000-12000 |

13000-15000 |

|

|

preform Specifications |

Suitable inner bottle neck (mm) |

|

20-25 |

20-25 |

20-25 |

20-25 |

|

|

|

|

preform max length (mm) |

|

150 |

150 |

150 |

140 |

|

|

Electricity |

Total installation power (kw) |

|

51 |

63 |

51 |

97 |

|

|

|

|

Heating oven total power (kw) |

|

46 |

58 |

46 |

92 |

|

|

|

Heating oven real power (kw) |

|

22 |

28 |

26 |

38 |

|

|

|

Voltage / frequency (V / Hz) |

|

380(50Hz) |

380(50Hz) |

380(50Hz) |

380 50Hz |

|

|

|

Allowed voltage fluctuation range |

|

±10% |

±10% |

±10% |

±10% |

|

|

Compressed air |

Pressure(bar) |

|

30 |

30 |

30 |

30 |

|

|

|

|

Air consumption(m³/min) |

|

4 |

4 |

6 |

8 |

|

|

Cooling Water |

Mold water |

Pressure(bar) |

4-6 |

4-6 |

4-6 |

4-6 |

Water chiller

5HP |

|

|

|

|

|

Temperature regulation range(℃) |

6-13 |

6-13 |

6-13 |

6-13 |

|

|

|

Flow rate (L / min) |

45 |

45 |

45 |

45 |

|

|

Oven water |

Pressure(bar) |

4-6 |

4-6 |

4-6 |

4-6 |

Water chiller

5HP |

|

|

|

|

Temperature regulation range(℃) |

6-13 |

6-13 |

6-13 |

6-13 |

|

|

|

Flow rate(L / min) |

22 |

22 |

22 |

22 |

|

Machine Specification |

Machine dimension (m) (L*W*H) |

|

3.8*1.3*2.3 |

4.3*1.3*2.3 |

4.8*1.3*2.3 |

5.5*1.3*2.3 |

|

|

|

|

Weight (Kg) |

|

3500 |

3800 |

4500 |

5000 |

|

|

Packing: Film covered or wooden box package According to customer needs

Delivery: 30-45 working days

Port: Shanghai or other port

Certifications and Factory Show

Eager to get you trust

Jiangsu Faygo Union Machinery Co., Ltd. adheres to the business philosophy of "integrity and win-win", adheres to the customer first and quality, serves customers with science and technology, adheres to technological progress, continuous innovation and continuous surpassing, and has become an enterprise with strength and scale in the rubber and plastic industry

We work closely with you to ensure your employees have the skills needed to ensure the safety and efficiency of line. We can serve you with the most sincere attitude and the best technology. Your satisfaction is our pursuit

Semi automatic bottle blowing Normally speed fully automatic bottle blowing Fully automatic Injection blowing

3-in-1 Bottle filling machine

Our Company

Professional Technology

1. FAYGO UNIONFaygo is a new high-tech entreprise covering 20000㎡, which specializes in researching and manufacturing blowing blowing machines

2. PRODUCTS

PVC/HDPE/PP-R pipe extrusion line, plastic sheet production line and relative auxiliary machines, PE film/PETbottles recycling line and Pelletizing line

3. MARKETING

Our products have been exported to Middle East, Southeast Asia, South America and Europe etc. We've received universal confirmation and trust from our customers

4. IDEA

Making good machine, Bing good person

Making good machine, Bing good person

Plastic profile/pheet extrusion line

Wood plastic composite ex

Making good machine, Bing good person

Plastic pipe extrusion line

Plastic recycling production line

We get along well with our friends from the Middle East, Southeast Asia, South America and Europe. Our products have been widely trusted and affirmed by our customers

We are looking forward to becoming your friends

1. High-quality equipment and highly competitive market prices can bring you more profits.

2. We have a one-year warranty and can provide long-term technical support.

3. Years of experience in the research of plastic extruders enable us to solve most of the problems and improve efficiency.

4. Send Your Inquire Details In The Below Click "Send" Now!