Faygo Union

Are you looking for a dependable and efficient bottle molding machine blowing? Look no further than the Auto 2 cavities high grade PET bottle blowing molding machine12 cavities grade high bottle blowing molding machine, proudly made.

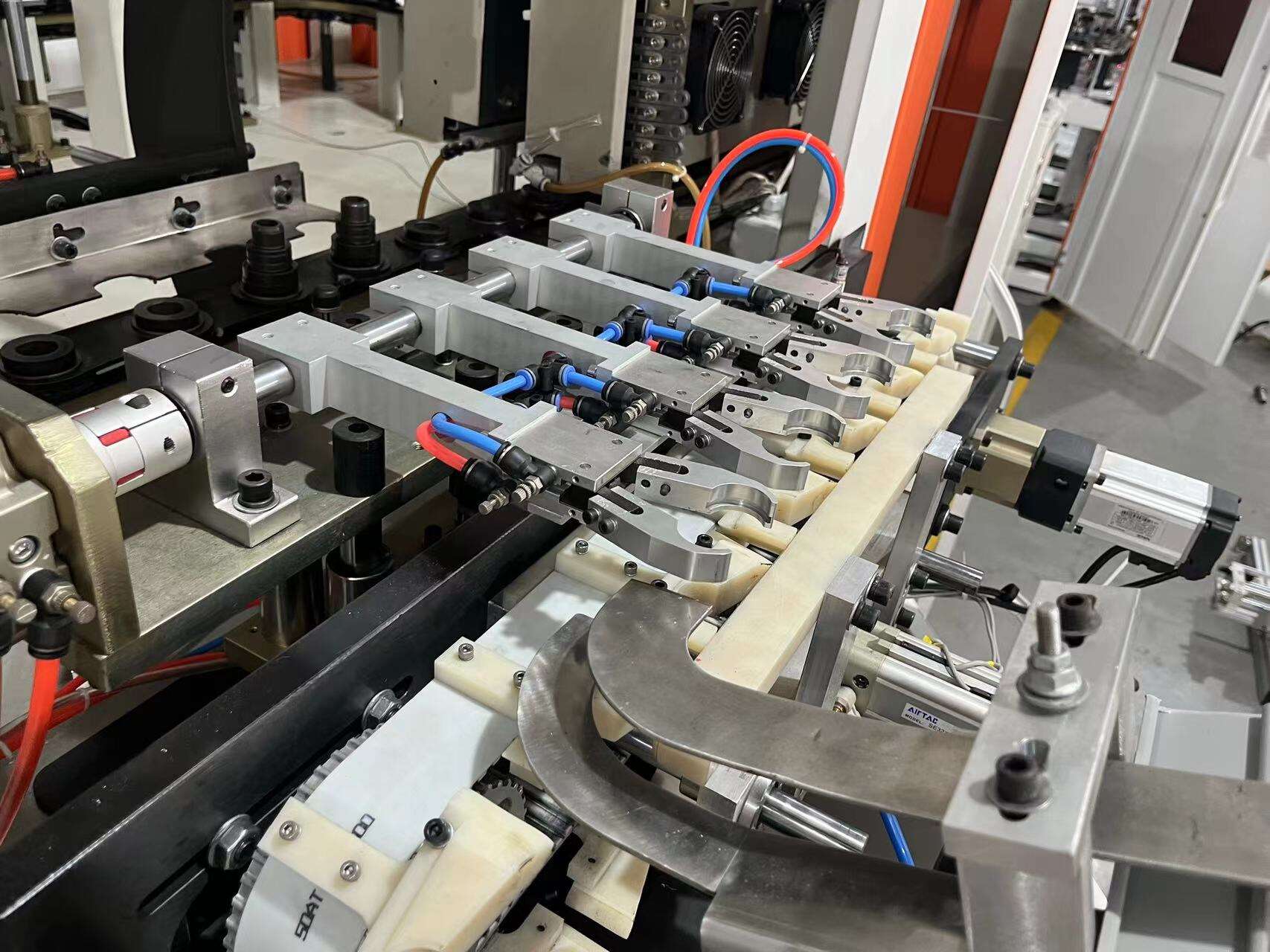

This machine versatile capable of creating high-quality PET bottles with ease. With two cavities, the Auto 2 can produce two bottles simultaneously, making it the most perfect choice for businesses that need to crank up production without increasing costs. The equipment can be highly customizable, allowing you to adjust settings to fit your needs unique.

The Auto 2 is built to last, with high-grade materials that ensure longevity and durability. It is made for ease of use, with an user-friendly interface that causes it to be simple to put up and operate. The device can be energy-efficient, assisting you spend less on utility costs while reducing your carbon footprint.

Faygo Union is proud to provide this high-quality bottle blowing molding machine to the customers. Our dedication to quality and customer care means with a product that meets your needs and exceeds your expectations that you can trust us to provide you. All of us of experts is often on hand to resolve questions and offer support, making sure you have a successful knowledge about our products.

Investing within the Auto 2 cavities high grade PET bottle blowing molding machine is an intelligent choice for businesses seeking to boost their production capabilities. Featuring its enhanced functions, durability, and user-friendly design, this machine is an excellent addition to any manufacturing unit. It is perfect for creating a wide variety of PET bottles, from small vials to large containers, rendering it a tool versatile can help you meet your entire production needs.

Don't settle for less than the best. Select the Auto 2 cavities High-Quality PET bottle blowing molding machine from Faygo Union and bring your production capabilities to your level next. Contact us today to learn more about this product incredible how it will help your organization.

Fully automatic blowing mould machines can produce a variety of shapes and sizes of plastic bottles and containers, including round, square, oval, and more. They are widely used in industries such as food and beverage, pharmaceuticals, cosmetics, andcleaning products, among others, and play an important role in modern industrial production.

PET bottle blowing mould machine is the high-end product of automatic blow molding machine, they are efficient, precise, high-quality, and reliable production equipment, and their advanced technology and automation systems make them a preferred choice for many manufacturers.

Faygo Union can produce various shapes and sizes of plastic bottles and containers, including but not limited to: -

Round Bottles: Fully automatic blow molding machines can produce round bottles in various shapes and sizes, such as water bottles, juice bottles, soda bottles, etc.

-

Square Bottles: Fully automatic blow molding machines can also produce square or rectangular bottles, which are commonly used for shipping liquid detergents, cleaning agents, soap solutions, etc.

-

Oval Bottles: Fully automatic blow molding machines canproduce oval-shaped bottles, which are commonly used for personal care products such as cosmetics, body washes, shampoos, etc.

- Irregular-Shaped Bottles: In addition to the above shapes, fully automatic blow molding machines can also produce bottles withunique shapes, such as flat bottles, triangular bottles, hexagonal bottles, etc.

In reality, we can produce many different shapes and sizes of bottles, depending on its design and configuration. If you have anyquestions, please contact us.

Model |

|

|

YDBA-2L-2 |

YDBA-2L-4 |

YDBA-2L-6 |

Remark |

|

|

Mold number(piece) |

|

|

2 |

4 |

6 |

|

|

|

Capacity(BPH) |

|

|

1800~2000 |

3500~4500 |

12000~13000 |

|

|

Bottle specification |

Max volume(mL) |

|

2000 |

2000 |

2000 |

|

|

|

|

Max height(mm) |

|

330 |

330 |

330 |

|

|

|

Round bottle max diameter(mm) |

|

105 |

105 |

105 |

|

|

|

Square bottle max diagonal(mm) |

|

115 |

115 |

115 |

|

|

Preform specification |

Suitable inner bottle neck(mm) |

|

20--25 |

20--25 |

20--25 |

|

|

|

|

Max preform length(mm) |

|

140 |

140 |

140 |

|

|

Electricity |

Total installation power(kW) |

|

52 |

52 |

72 |

|

|

|

|

Heating oven real power(kW) |

|

25 |

30 |

45 |

|

|

|

Voltage/frequency(V/Hz) |

|

380(50Hz) |

380(50Hz) |

380(50Hz) |

|

|

Compressed air |

Pressure(bar) |

|

30 |

55 |

66 |

|

|

|

Cooling water |

Mold water |

Pressure(bar) |

4--6 |

4--6 |

4--6 |

Water chiller |

|

|

|

|

|

|

Temperature regulation range(°C) |

9--13 |

9--13 |

9--13 |

(5HP) |

|

|

|

Oven water |

Pressure(bar) |

4--6 |

4--6 |

4--6 |

Water chiller |

|

|

|

|

|

Temperature regulation range(°C) |

6--13 |

6--13 |

6--13 |

(5HP) |

|

|

Machine specification |

Machine dimension(m) (L*W*H) |

|

3.3X1.8X2 |

4.8X1.8X2 |

5.5X2.5X2.2 |

|

|

|

|

|

Machine weight(Kg) |

|

2500 |

3500 |

6000 |

|

|

|

Preform Loading

The preforms are loaded into the hopper of the machine's loading system, which can hold hundreds or even thousands of preforms depending on the size of the machine

Heating

Once the preforms are loaded, they are transported to the heating station where they are heated to the required temperature using infrared heating lamps. The temperature and duration of the heating process are carefully controlled to ensure that the preforms are heated evenly and not overheated

Stretching

Next, the preforms are transferred to the stretching station where they are stretched using a stretching rod. This process ensures that the preforms are the correct length and diameter for blowing

Blowing

Once the preforms are properly stretched, they are moved to the blowing station where high-pressure air is used to blow the preforms into the desired shape. The molds can be quickly and easily changed to produce different bottle shapes and sizes

Cooling and Ejection

After the bottles are blown into their final shape, they are cooled using chilled water or air before being ejected from the machine. The cooling process ensures that the bottles maintain their shape and do not deform due to heat

Quality Inspection

Finally, the bottles are inspected for quality control purposes. Any defective bottles are removed from the production line, and only the bottles that meet the required quality standards are allowed to proceed to the next stage of the production process

Faygo Union Machinery Co., Ltd. is a professional enterprise which integrates designing, manufacturing and offering the turn-key project to our partners.

For decades, Faygo Union has dedicated herself to the packaging machinery of water, beverage, daily use chemical and edible oil. We have supplied over 70 countries and regions with the following products: air compressors, PET blowing machine, water treatment, washing-filling-capping assembly line and barreled drinking water assembly line

Faygo takes “making good machine; being good person” as its principle, and we will this philosophy throughout all aspects of production, innovation and strive to achieve beyond optimize product quality for our customers

Our Services & Strength

We provide 24 hours on line service, all life technical support, cost price spare parts in stock. Warranty is 1 year, any quality problem, we can send free spare parts or change new one