The Faygo Union’s 110~630mm OPVC Biaxially Oriented polyvinyl chloride pipe production line with factory price is an effective and dependable solution in the manufacturing of top-notch pipelines. This revolutionary product was made to generate a number of pipes, from 110mm to 630mm in diameter, making it a versatile system in any manufacturing line.

This manufacturing line has a various features that set it apart from other rivals available on the market. This was made to help you to reduce work expenses while increasing effectiveness. Furthermore, this functional system was made with high level technology that guarantees precision and dependability through the manufacturing procedure.

This was made using high-quality materials that which ensures durability. The unit can withstand the rigors of day-to-day usage, supplying exemplary value for your money. The manufacturing line was built to be easy to use, having a user-friendly screen that helps it be an easy task to run and keep.

The Faygo Union’s 110~630mm OPVC Biaxially Oriented polyvinyl chloride pipe production line is a green choice which decreases waste and minimizes ecological effect. This will be attained by using higher level manufacturing techniques and reduce the amount of garbage employed in the technique.

One of the primary benefits of this system is its factory cost. This comes at an affordable cost, making it perfect for organizations of all the sizes and spending plans. This is an advantage for companies that are looking to get top-quality manufacturing line but cannot afford to it

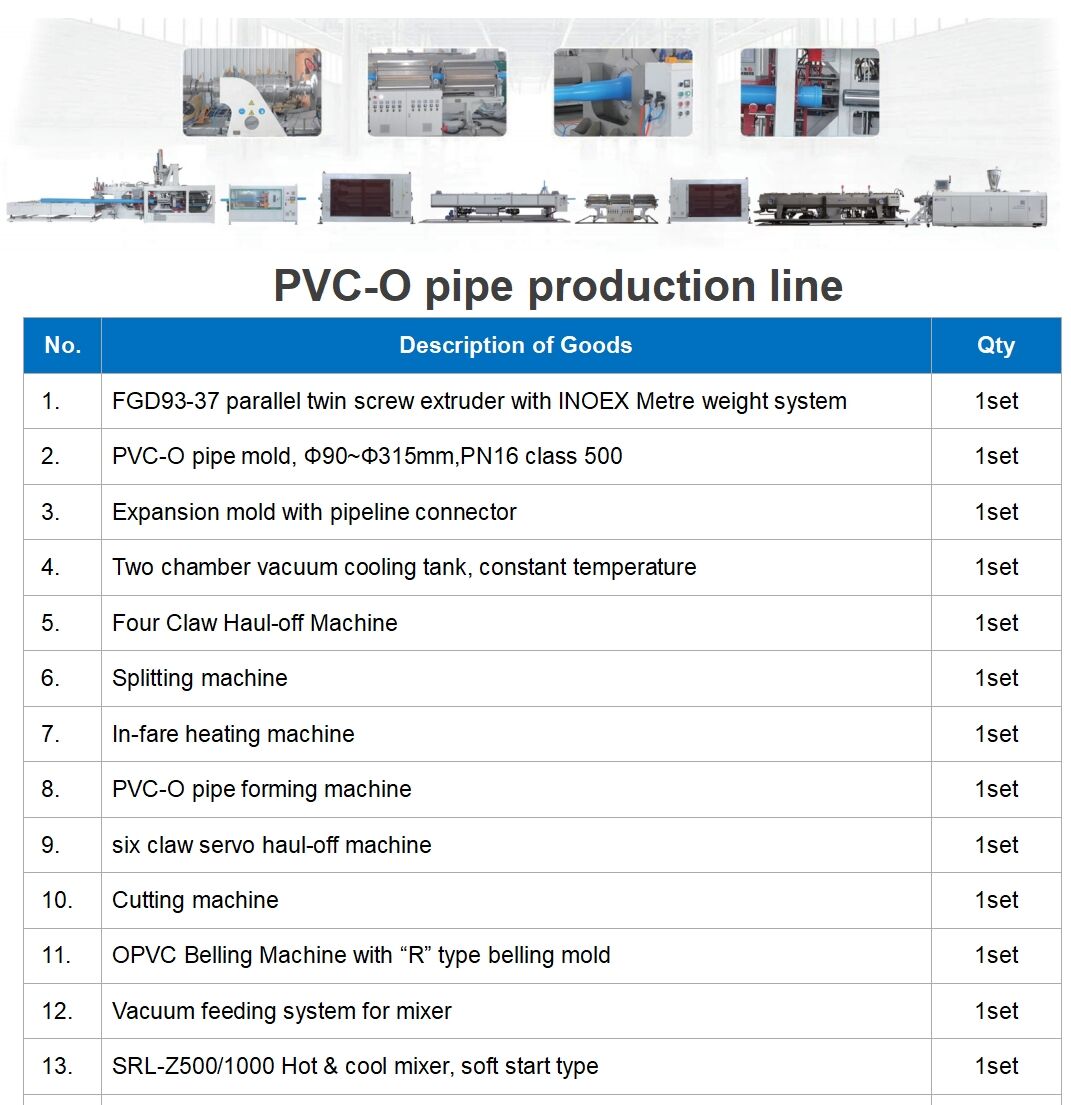

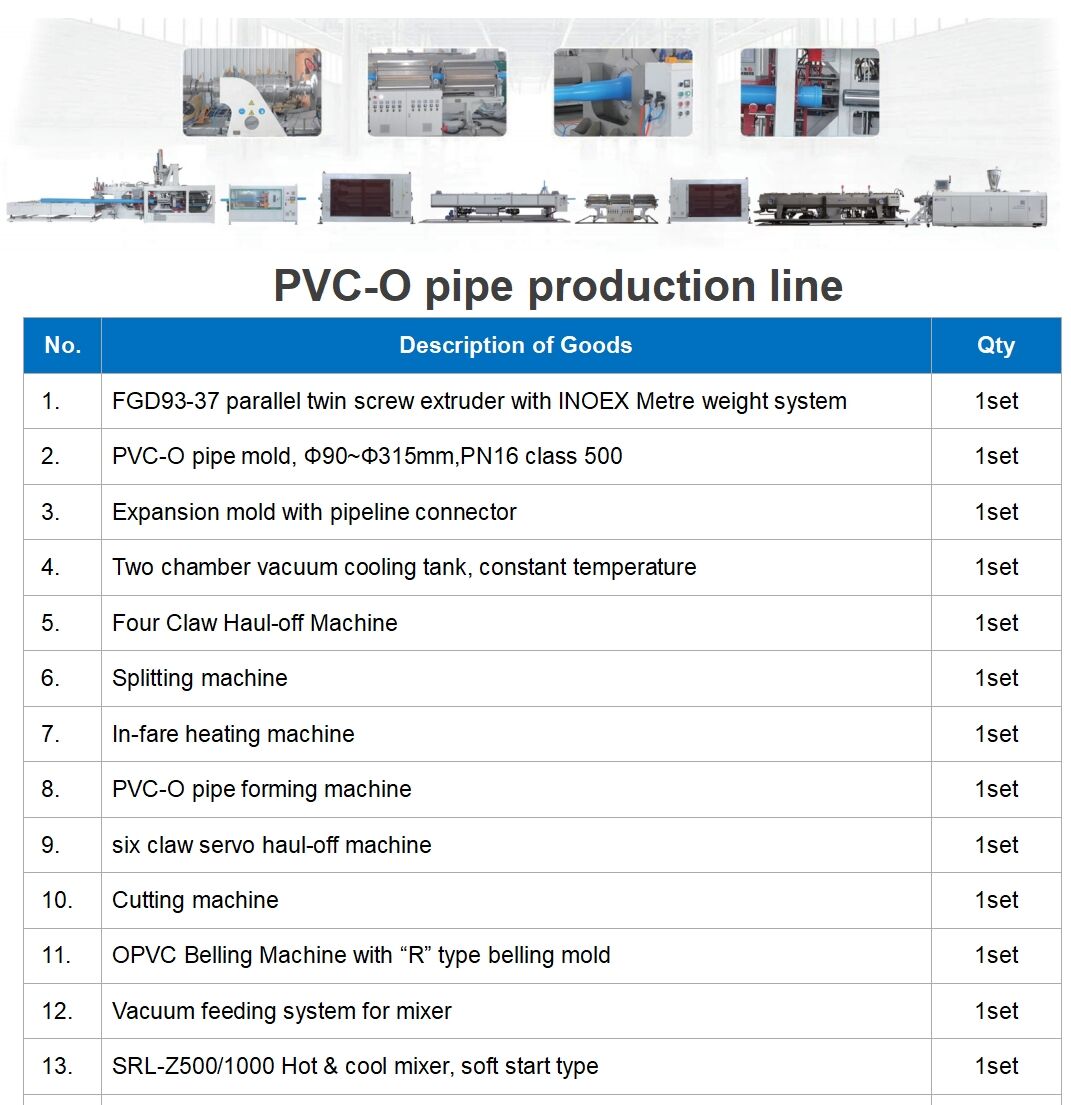

Oriented polyvinyl chloride OPVC PVC-O pipe production line

This PVC-O pipe extruder making machine use newest technology to make plastic pipes. With special biaxial stretching technology, it can largely reduce the material cost for pipe production, more than 50%. It is become more and more popular now days

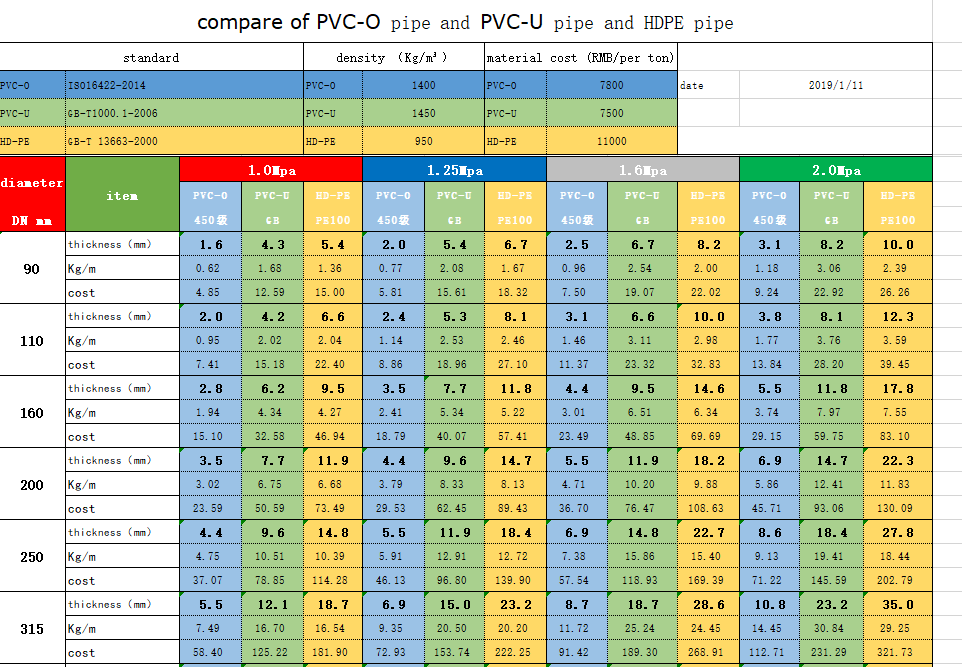

Biaxially oriented polyvinyl chloride (PVC-O) pipes are pipes manufactured through a special oriented processing technology. This processing technology is to stretch the PVC-U pipes produced by the extrusion method in axial and radial directions. The long-chain PVC molecules in the pipe are arranged Biaxially to obtain a new type of PVC pipe with high strength, high toughness, high impact resistance and fatigue resistance, which is far better than ordinary PVC-U pipes. At present, the strength grade of PVC-O pipe is up to 500, and there are 400 grades and 450 grades. The design coefficients are C=1.6 or 2.0. Among them, the design coefficients of 450 and 500 strength materials can be C=1.4

Advantages of Oriented polyvinyl chloride PVC-O pipes

1. Anti-corrosion performance, acid and alkali corrosion resistance, also suitable for chemical pipelines

2. The pressure-bearing performance is greatly improved, and it is more suitable for fire-fighting buried pipelines

3. High temperature resistance and low temperature resistance are greatly improved

4. It solves the shortcomings of low strength of HDPE pipes and high brittleness of PVC-U pipe

5. Become a superior alternative to these two main water supply pipelines

6. Excellent elasticity and excellent anti-cracking ability. Due to the improvement of the production proce

Technical data

| Model/data |

Pipe diameter |

Extruder model |

Speed |

Max capacity |

| FP250 |

110-250mm |

FGD78 |

1.5-8m/min |

300kg/h |

| FP315 |

160-400mm |

FGD93 |

0.5-5m/min |

500kg/h |

| FP630 |

400-630mm |

FGD114 |

0.1-2m/min |

800kg/h |

PVC-O pipe is the latest evolutionary form of PVC pipe pipe. By using a special orientation process (biaxial stretching technology), stretching and radial stretching, so that the long-chain PVC molecules in the pipe Biaxially arranged in order to obtain high strength, high toughness, high impact resistance, crack resistance of the new PVC pipe

The stretching orientation process of polymer materials is the process of the molecules arranged from disordered to ordered under the action of external force under the condition of temperature between the glass transition temperature and the melting temperature (usually near the softening point). Biaxial stretching is a process in which a material is Biaxially stretched to make the strength perpendicular to the the stretched surface of the biaxial stretching that superimposed on the strength of the stretched surface direction, thereby increasing the strength of the material in the direction of the stretched surface

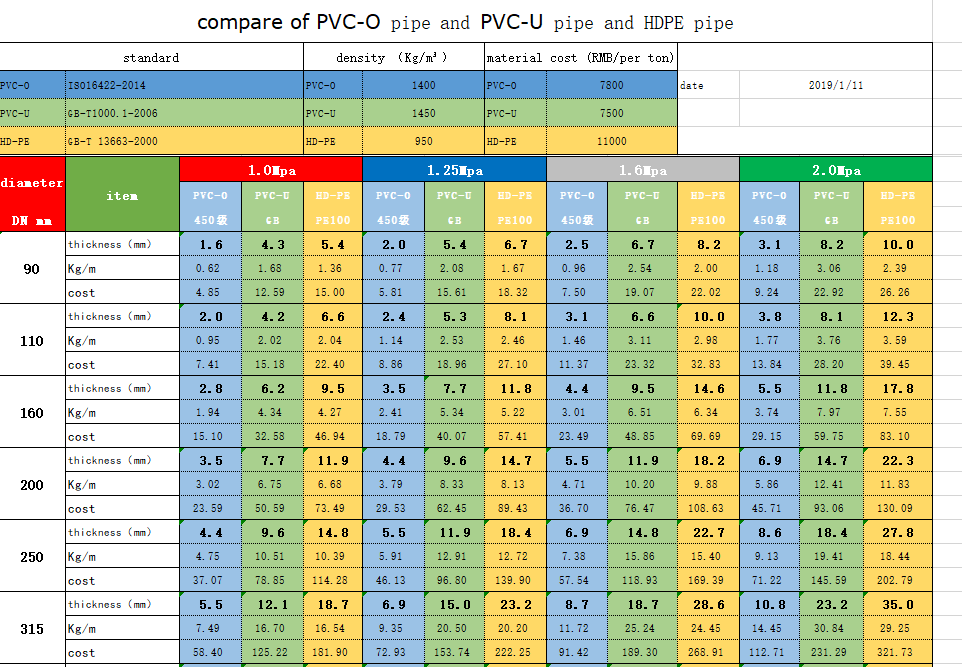

Compare to normal PVC pipes, the pipe wall thickness of OPVC is very thin, but it can endure high pressure. With PVC-O pipe making machine, the client can largely save the material cost

For more details about our PVC pipe making machine, welcome to contact with us. We will reply you in 24hours