Blow molding machines are a wonder of modern industry which is an absolute must for manufacturing just about any kind imaginable hollow plastic component. The process of molding hot plastic to air pressure in a custom mold and subsequently cooling is all that it takes for the production. They are used to manufacture basic items, for example, water ball and nourishment holder bricks just as fun toys which exhibits the flexibility of blow forming machines.

After blow moulding technology Blow Moulded Water Tank Manufacturing Process imageThis is a fairly real and conventional way of manufacturing water tanks, which has now been metaphorically buried by the majority types. This cutting edge technology have has empowered vendors to manufacture top notch water tanks at very affordable prices. These are some very hardy tanks, they have a lighter than normal design and can hold plenty of rainwater which makes them ideal for home use (domestic) or commercial applications such as supplying water to the grounds at outdoor events.

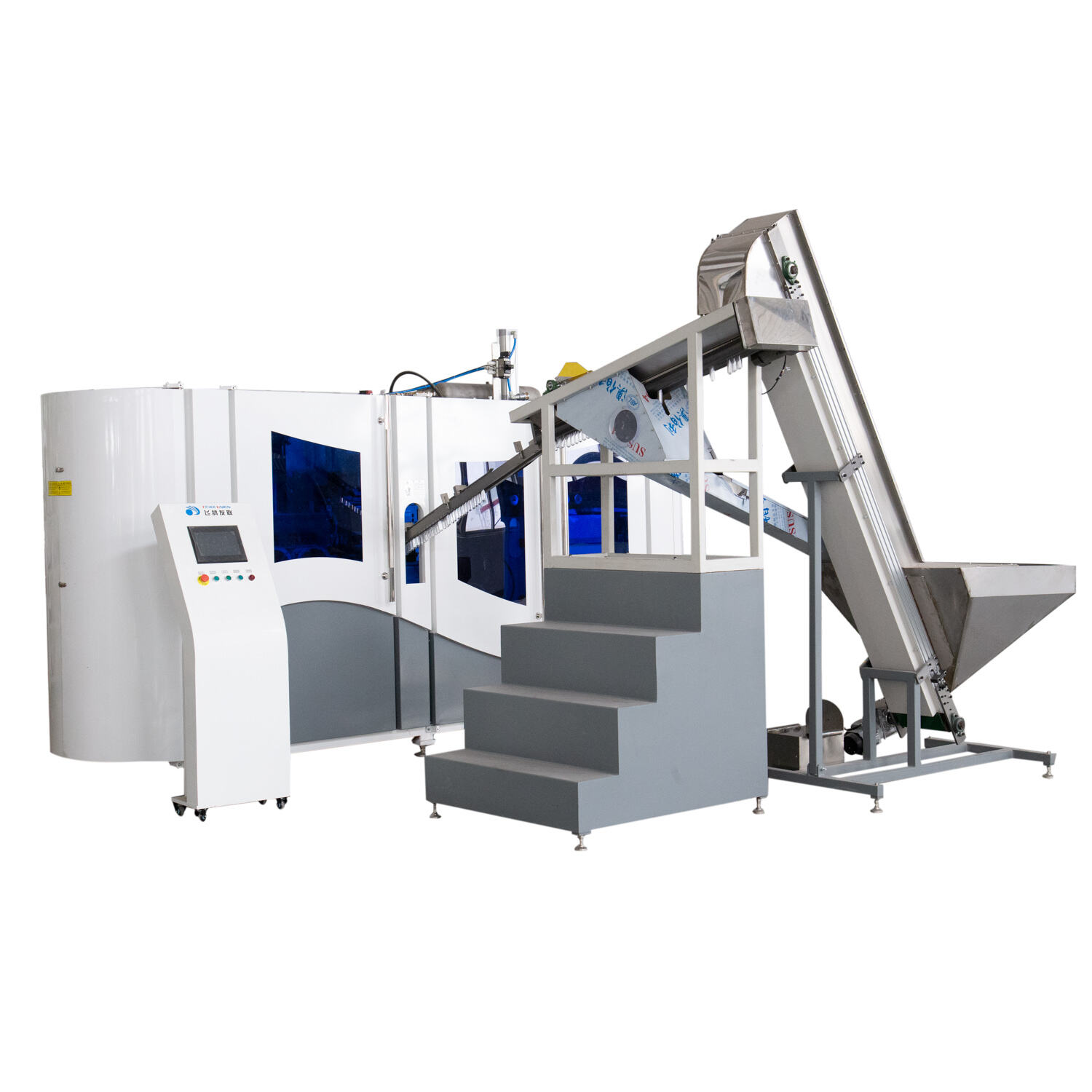

Water tank blow moulding machine is a kind of machinery only designed for water tanks. The whole process should be agreeable with the expectations of customers, innovatively designed using next generation equipment to manufacture even more number of water tanks in relatively low period so that it provides efficient and productive.

The unique design of water tank which improve the ease use and low maintenance cost in blow moulding machine. It comes with a friendly interface and it is mainly well-built using quality materials hence durable for use in the long-term. Both in terms of size and engineering sophistication, the "cored roaster" is being tuned to provide more material-saving not only weight savings but also environmental controls on an industrial scale.

There are multiple benefits of having a water tank blow moulding machine for manufacturing needs. Free of charge That the cost savings from our way are among the factors why we could use you similar water storage tanks a lot more budget friendly as contrasted to various other making techniques. Secondly, the process is a rapid cost-effective simple solution of manufacturing huge quantity water tanks in least time. Last but not least, the water tank blow moulding machine is engineered for high performance to support in producing excellent standard yet larger and even sized water tanks consistently.

In a nutshell, the blowing machine of water tank is an intoxicating combination with changing existing trends forever for the water tanks. In additional to boosting the production of high-end water tanks more cost-effectively, it also helps in improving efficiency and yield. With user-friendly interface, latest technology and uniform performance capabilities; the water tank blow moulding machine is considered perfect for all types of businesses looking forward to getting better at their water tanks productions.

FAYGO UNION GROUP now more than 500 customers spread across countries like UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. From Europe, America (Canada, Mexico, Brazil Venezuela, Chilly, etc.) and Saudi Arabia, Iran Syria, India, Thailand Indonesia Thailand Indonesia. Many customers coming from Africa as well as Asia. Our factory, which is located in Zhangjiagang City, has an area of 26650 square water tank blow moulding machine. only takes around two hours driving to SHANGHAI International Airport.

Online service: sales managers are 24 hours online are able to provide customers with quick reply. Please contact us if you have any questions regarding products. Patents certificates: Faygo Plast has 13 national patents, which include 8 invention patents. are water tank blow moulding machineimproving our products, and we offer the latest technology to our customers. product have CE and ISO certification.

FAYGO UNION GROUP has 3 branches factories. One them is FAYGOBLOW which water tank blow moulding machineproduces blow molding machine PET, PE etc. FAYGOBLOW has five patents invention and 8 patents utility models. FAYGO PET blow moulder among fastest and most efficient design its kind in the world. second plant is FAYGOPLAST, which make plastic extrusion equipment, which includes the plastic pipe extruding line and extruding lines made of plastic profiles. Particularly, FAYGOPLAST provides highest speed up to 40m/min PE PPR pipe line.

increase output(doubled) Rotary perform uploading a soft and continuous manner. run continuously water tank blow moulding machineof step-by-step, movement more soft. Reduce Bad Bottle Rate. Reduce amount of bad bottles.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy