Do you enjoy drinking water? Ever wondered how the water bottles we use everyday was made? It’s pretty interesting! These water bottles are created by the help of a specific machine known as waters bottle blow moulding machine. This machine has one important task, and that is ensuring we always have the bottles available when need to hydrate.

A water bottle blow moulding machine is an unusual device that produces plastic drinking and consumable jars. They operate very quickly, so they can make many bottles in a short period of time. This is great because people guzzle water and we need a well stocked supply of bottles. The machine is not only fast, but it can also create bottles of different shapes and sizes. Like a small bottle for kids or the big liter jar for adults. To begin with, some of the bottles can be round like a ball or square like a box or they can come in diverse colors so there is for sure something that suits everyone!

Benefits aside, this space-age machine …. how exactly does it work? With a special technology, it is used to make the bottles we use. The method begins using a grain of pellet (plastic). That pellet is then melted. The plastic is then melted and formed into a tiny tube, called preforms. Now, imagine if you could see a preform - it would be reminiscent of an tiny test tube! This preform is then loaded inside the machine.

A bottle-shaped mold inside the machine The shape is cooled by water so that its original form remains the same. From there, a preform is inflated by blowing air into. Here the melted plastic is pushed by air to fill completely into a mold, turning the preform in fully bottle. Well it is simply wonderful how air can form plastics!

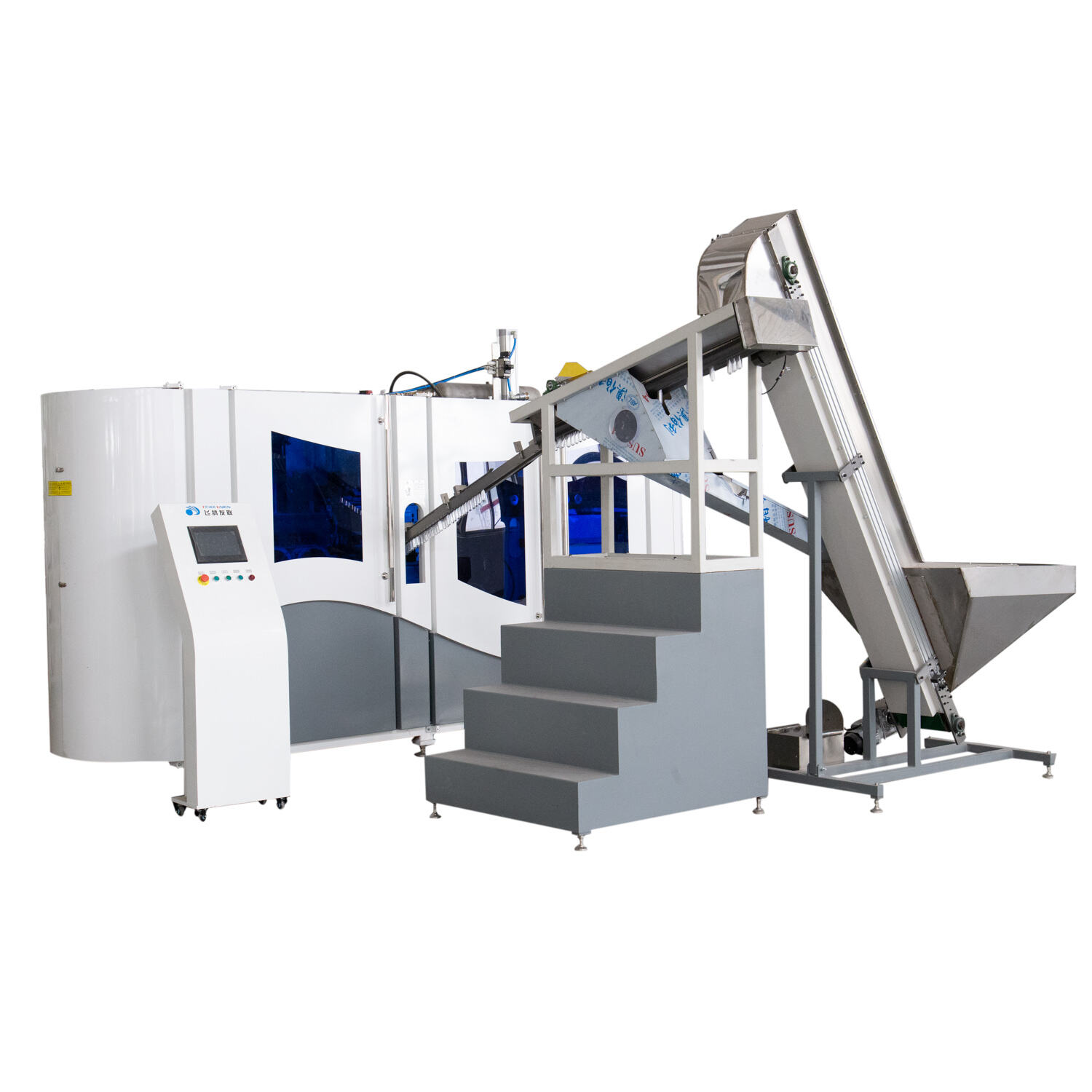

The bottles can be created in multiple numbers at the same time and it is one of best features available for this machine.... because it literally just works. What does that mean? This fulfills that the machine can complete everything on its own without relying upon somebody to be present with it all of eh time. This is the robotic arm delivering preforms into the machine, and a conveyor belt transporting finished bottles to another part for packaging.

The water bottle blow moulding machine is an excellent investment for any company that produces bottles. Why that is will make sense with what I previously said (it virtually never breaks down). Effectively, this allows us to have the thing keep running for many hours on end without ceasing and stopping up like a business... They need to ensure that they can keep bottle surface without having any delays which in turn may prove expensive or time-consuming.

The good thing about this water bottle making machine are, it is a three cavity and pneumatic type of machine comes with manual preform loading for ordinary PET bottles up to 1.5 Ltrs along with the change parts as long as neck diameter between min/max: from 30 mmmax/1200-150 mmgradually increase in laser treatment facility clamping unit power consumption then perfectly manufactured purifying lube system ensure proper perform cooling through further blowing chilled in wide performing procedure function displaying sample testing by injection quality assurance. If a certain company wants to manufacture an entirely new type of bottle, one can easily reconfigure the machine and create another mold for it. The ability for companies to offer more bottles is a great help from this flexible stand point.

Now FAYGO UNION GROUP has more than 500 customers across different countries including UK, Spain, Germany, Norway, Switzerland, Italy, Turkey Russia etc. From Europe ,America, Canada, Mexico, Brazil, water bottle blow moulding machine, Chilly etc from America, Saudi Arabia, Iran, Syria, India, Thailand, Indonesia etc. from Asia, and many customers from Africa. factory, situated Zhangjiagang City, has an surface of 26650 square metres. From the airport, factory only two hours.

FAYGO UNION GROUP made up of 3 branches. FAYGOBLOW is blow molding machine producer for PET, PE other materials. FAYGOBLOW is owner of five patents invention and 8 patents utility models. FAYGO PET blow molder is fastest most effective water bottle blow moulding machineits kind in the world. second manufacturing facility is FAYGOPLAST. makes plastic extrusion machines for example, extruding lines made of plastic pipe, and extruding plastic profiles. Particularly, FAYGOPLAST can offer PPR and PE pipes at speeds up to 40m/s.

More output (doubled) Rotary perform continuous running instead of stepping step-by-step run more smoothly. Reduce Bad Bottle Rate. Only two heating boxes, with each head's distance the heating source decreased to 38.1mm, which can reduce 30% more water bottle blow moulding machinethan the conventional model, which is about 130000kwh electric power, so an entire year, based on 8 hours per day, could reduce 20000USD only heating power. More than 100+ countries choose to be partners and my company after service team.

sales representatives all hours of the day to provide fastest possible service. invite you contact us if have any queries about products. Patents and certification: Faygo Plast has 13 national patents. Among them are 8 invention patents. We are always water bottle blow moulding machineour products provide the latest technologies our customers. products have CE ISO certificates

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy