This type of work is something that requires a lot to consider; especially if you look at the detail in plastic bottle making. Each of these bottles can be quite distinctive in shape and size, rendering them to many other types devices they are utilised for. Blowing moulded these bottles using Stretch Blowing process. And that is an important process which it does to create a strong and useful container.

The blow moulding technique used for the production of PET bottles includes this step known as stretch blow moulding where In order to be blown into a bottle, Plastics are first melted. This is through the plastic subliminal messages heating up until they turn into a soft goozy mush. The molten plastic is then stretched and thinne to form the fiber. The soft plastic is expanded by blowing air into it, after stretching. This helps the plastic to become in bottle shape like blowing up a balloon. At long last, the plastic is cooled and solidified. After it cools, its ready to be packaged for other products and beverages!

This is one of the advantages of stretch blow coming back: it allows companies to release bottles that are bespoke to them. This makes them able to produce unique and distinct bottles. This makes them stick out on store shelves when compared to the regular bottles which could help influence a purchase. A colorful or oddly-shaped bottle can make it easier to find among all the plain ones.

Stretch Blow Moulding is a smart way to make bottles, but it's also both very fast and high in quality. This allows companies to produce a mess of bottles quickly. But this process also gives them the molds they need to produce bottles that are perfectly sized and molded so everything fits inside just right. You can avoid the product spills, and safe at its place.

There are of course numerous reasons why packagers would prefer to use stretch blow moulding for producing the bottles they will one day deliver. Significantly cheaper than all other methods of producing plastic bottles. This way makes companies save money as saving is one of their priorities. The second good news of this process is that drives in better environment, uses less plastic and yes waste around! Companies can reduce pollution and save our planet by using less plastic! Finally, the bottles are durable which makes them perfect for products to be hold and stand nicely. By this, it means the products in bottles are less likely to break.

A novel way of making bottles today is known as stretch blow moulding. It enables companies to craft unique bottles that will stand out amongst the competition. It is also a wise and green way to manufacture high-quality bottles. This method of production can be used guilt-free by companies as it results in products that are sustainable and does not require a lot of other resources.

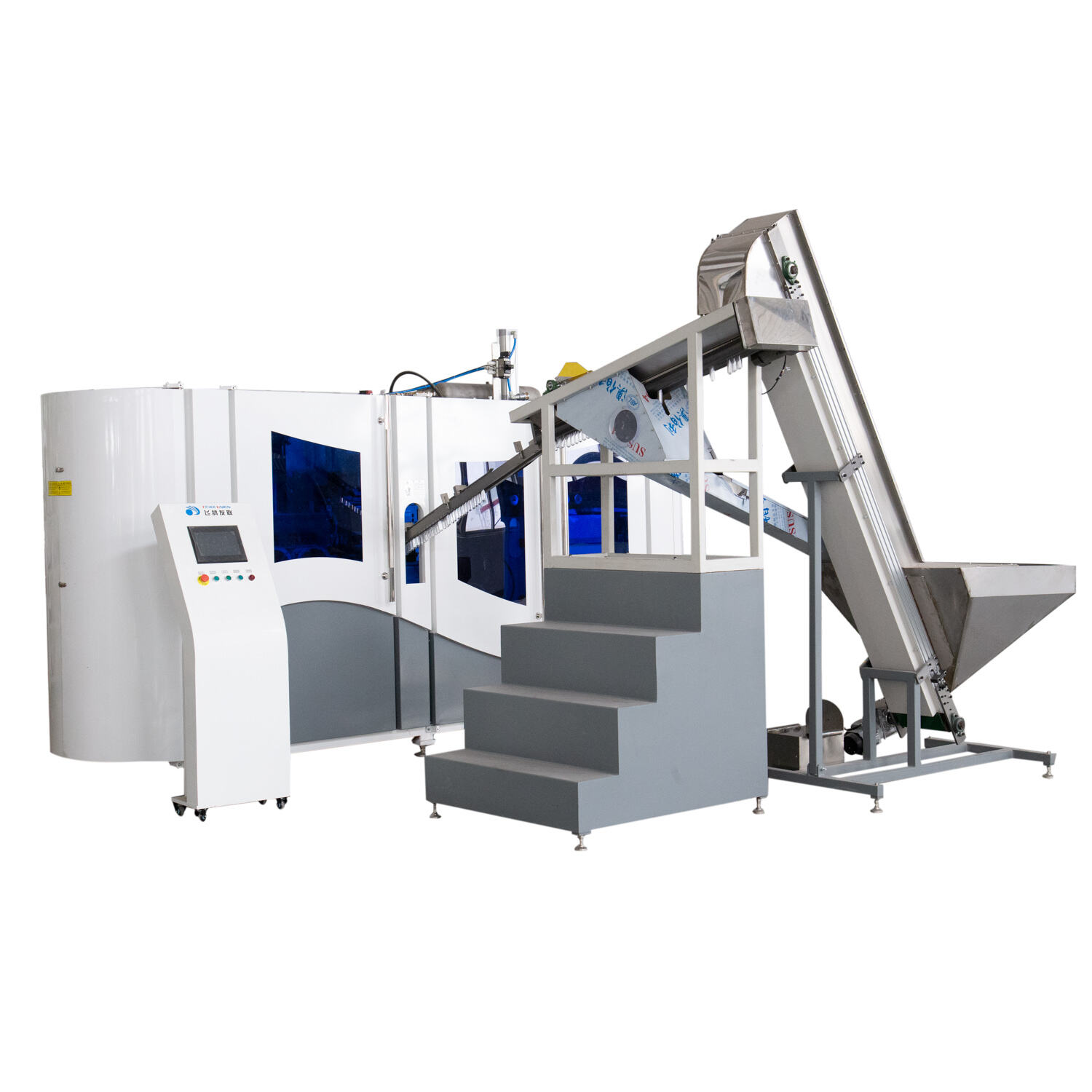

FAYGO UNION GROUP has 3 branch factories. One FAYGOBLOW that designs manufactures blow molding machine PET, PE etc. FAYGOBLOW has 5 patents invention, as well as 8 patents for utility models. FAYGO PET blow moulder is the fastest and most efficient design available the stretch blow moulding. second manufacturing facility is FAYGOPLAST, which make plastic extrusion machinery, including the plastic pipe extruding line and extruding line made of plastic profile. Particularly, FAYGOPLAST provides high speed up to 40 m/min PE, PPR pipe line.

Now FAYGO UNION GROUP has more than 500 customers across different countries including UK, Spain, Germany, Norway, Switzerland, Italy, Turkey Russia etc. From Europe ,America, Canada, Mexico, Brazil, stretch blow moulding, Chilly etc from America, Saudi Arabia, Iran, Syria, India, Thailand, Indonesia etc. from Asia, and many customers from Africa. factory, situated Zhangjiagang City, has an surface of 26650 square metres. From the airport, factory only two hours.

More output (doubled) Rotary perform continuous running instead of stepping step-by-step run more smoothly. Reduce Bad Bottle Rate. Only two heating boxes, with each head's distance the heating source decreased to 38.1mm, which can reduce 30% more stretch blow mouldingthan the conventional model, which is about 130000kwh electric power, so an entire year, based on 8 hours per day, could reduce 20000USD only heating power. More than 100+ countries choose to be partners and my company after service team.

Service online: sale managers are available 24/7 give customers most quick answers. invite you to contact us have any stretch blow mouldingabout our products. Patents certificates: Faygo Plast has 13 national patents, including eight invention patents. keep improving our products and are able to provide the most recent technology our customers. product have CE and ISO certification.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy