We probably use plastic tools every day, Well this can include bottles for drinks, containers to put food in and also try some colorful toys that are not so harmful but the associated parts gets more complex when it goes into something:Event applicable machinery. Ever wondered how those are made? It’s fascinating! They are made using blow molding; The process works by blowing melted plastic into a special mold that is shaped to create this hollow side-striped bumpy object. This way of production is not new, but for now we have special machinery that improves a blow molding process in terms to quality and speed.

What if you had the capability of producing any type or shape of plastic item? I need you to pause... and then visualize that more rapidly (and even cheaper than has ever before been done! Our special blow molding machine can serve the same purpose for you. The array of products this brilliant machine can produce is endless. It produces things from tiny toy animals like adorably tiny puppy and kitty figurines, to large water tanks that can hold a lot of...water. Even more exciting is that it works with various types of plastic materials such as polyethylene, polypropylene and PVC. Therefore, it is very flexible and can be applied to many types of product.

The blow moulding machine has been designed so that it not only saves energy but is also money off your pocket which I think great. It uses less energy than old methods to making things. Which means it is more sustainable for the planet we all live on, which of course matters most! It also is potentially more efficient, and requires less workers than other methods of operation. This can ultimately end up saving companies a huge amount of money. If companies spend less, they can sell their products at lower prices to the people buying plastic!

---The plastic industry is old, but thanks to the development of high-end blow moulding technology its end product can not only more durable and reliable; it may already be manufacturable faster! The system uses a blow moulding machine to produce high quality plastic products with less errors. This leads to lesser number of defects in the items being produced, and can be manufactured a day faster. The plastic supply has been growing stronger with the help of this new emerging technology, and companies now are in front of their competition. As a result, they deliver better products to their customers.

Plastic items are required by businesses and every one has different sets of needs. For car companies, they require durable plastic parts that can withstand the heat and pressure in a vehicle as opposed to toy companies which need easily cleanable and safe plastic toys for kids. Our blow molding machine is special and can be modified to what you need for have the same manufacturing capabilities. You can design them for products of a particular shape, size, material to produce one-shot waylays suitable to the manufacturing process - whatever you need in your industry. This implies that a corporation will perpetually keep on creating ample for the traditional kind of plastic things mainly due to which sort is before long conferred.

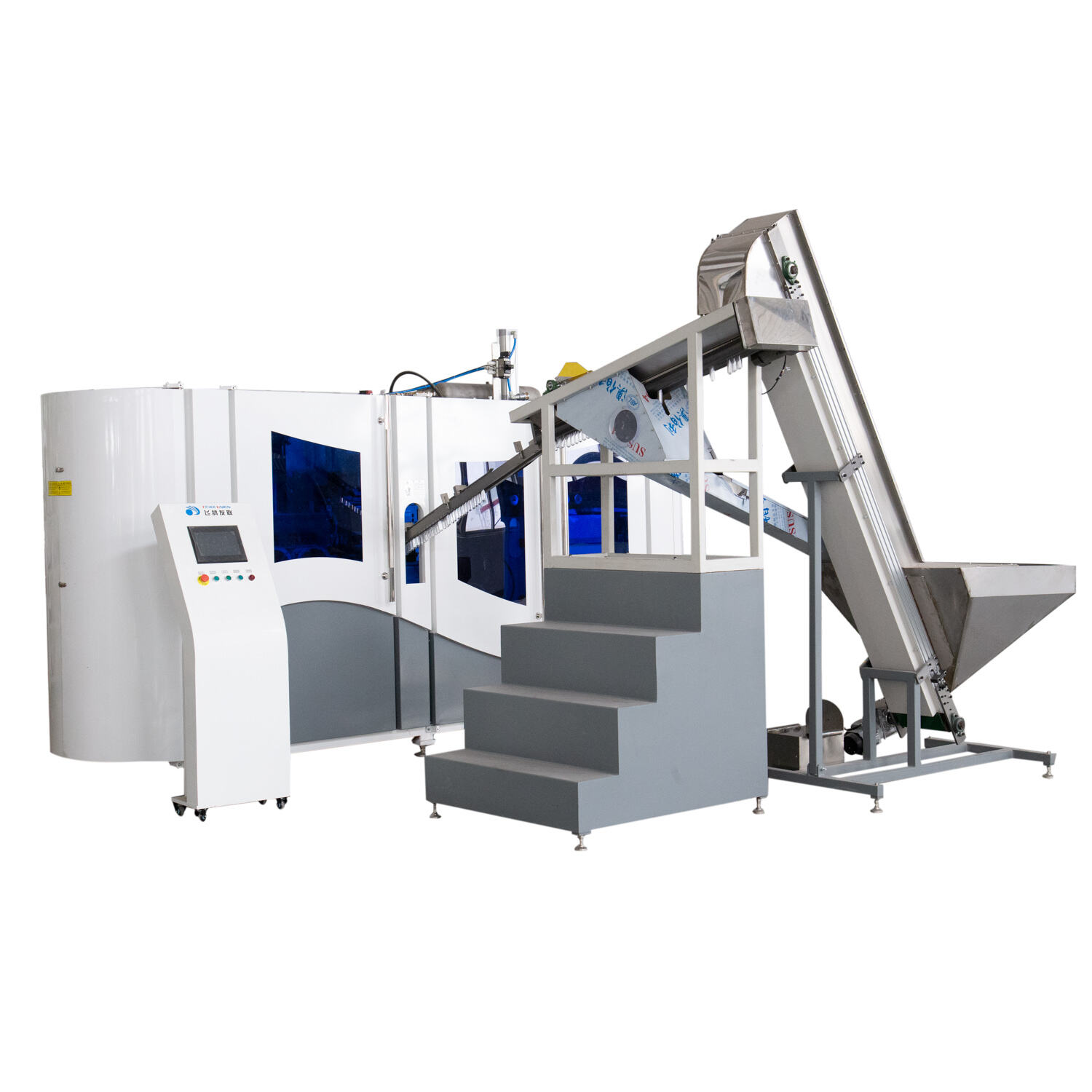

FAYGO UNION GROUP made from 3 branches. One is FAYGOBLOW that designs manufactures blow molding machine PET, PE etc. FAYGOBLOW has five patents invention, 8 patents utility models. FAYGO PET blow molding machine is among the most efficient fastest designs plastic blow moulding machinethe globe. second factory FAYGOPLAST which produces extrusion machines made of plastic, such as plastic pipe extruding line, plastic profile extruding line. Particularly, FAYGOPLAST is able to supply the highest speed of up to 40m/min PE PPR pipe line.

sales representatives are 24/7 to ensure best possible service. you require any further information about products, don't hesitate contact us. plastic blow moulding machinePlast holds 13 national patents and 8 invention patents. constantly improve products order to provide most advanced technology our customers. products are certified by ISO and CE. CE and ISO certificate.

increase output(doubled) Rotary perform uploading a soft and continuous manner. perform continuous running instead step by step and movement is more gentle. Reduce number faulty bottles. fitted with two heating box, each heating head distance minimized 38.1mm, which can reduce 30% more electricity than the plastic blow moulding machinemodel, which is about 130000kwh electrical power, which means one year based on 8 hours a day, you could save you 20000USD only on heating power; Over 100 countries choose to be partners as well as my own after-service team.

FAYGO UNION GROUP now has over 500 customers different countries, including UK, Spain Germany, Norway Switzerland Italy Turkey Russia etc. From Europe ,and America, Canada, Mexico, Brazil, Venezuela, Chilly etc from America, and Saudi Arabia, Iran, Syria, India, Thailand, Indonesia etc. A lot of our plastic blow moulding machinecoming from Africa and Asia. Our factory, which located Zhangjiagang City, covers total area f26650 square metres. From airport, factory just two hours.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy