Have you ever thought about the process of birth of those Funko Pop characters, or that plastic bottle we use for water and even very packaging materials which we throw after buying items? It's quite fascinating! Blow moulding is one of strategy which used to produce those items. As we speak, types and products that are used by us the place liquid plastic is blown right into a mold in order to blow air.

A type of one blow moulding machine which used in a variety with another processing categories and among them also are the equipment this as comprehensive. HDPE Blow Molding Machine HDPE (high-density polyethylene) is one type of plastic that you don't come across every day. It is basically heat, moisture and chemical resistant to a high level of standard which makes it as an ideal material for many applications.

Plastic manufacturing gains various numerous benefits with the help of HDPE blow moulding machines around same. For starters, these are very efficient machines that can create plastic parts at the rate of thousands per minute. This is an incredibly beneficial point, especially when it comes to rapid packaging for industries who have a high volume of products to answer consumer demands. In addition, the technology used in products made from HDPE blow molding machines ensures durability and quality. Providing a medium-high strength, HDPE plastic, therefore products made from this material are reliable and durable. HDPE - a safe and non-toxic material, approved by the FDA for food packaging (and many other uses besides).

HDPE Blowing moulding The breakthrough of this technology gave the plastic industry a shot in the arm. This technology is bringing out the best from plastics as it helps in removing limitations on materials, enabling manufacturers design parts which are no longer confined to conventional thought process and offering higher strength, durability combined with greater freedom of use. HDPE Bottles are also available in several sizes, shapes and designs with options for colours; HDPE Blow Moulded Products. Users can mix this type of plastic with other materials such a fiberglass or metal, to create the stronger more tough product.

These are the main developments that will be made through HDPE blow moulding machines in terms of providing ways for PET products to reach a wider audience on daily basis. This allows us to produce products VERY quickly, and also at a far lower cost than the typical manufacturing means. Because HDPE plastic can be converted back into virgin material it is an industrial sustainable consumer form of recyclable packaging. As more and more companies begin to invest in HDPE blow moulding machines, the range of innovative environmentally friendly wares that are available for purchase on store shelves will only increase.

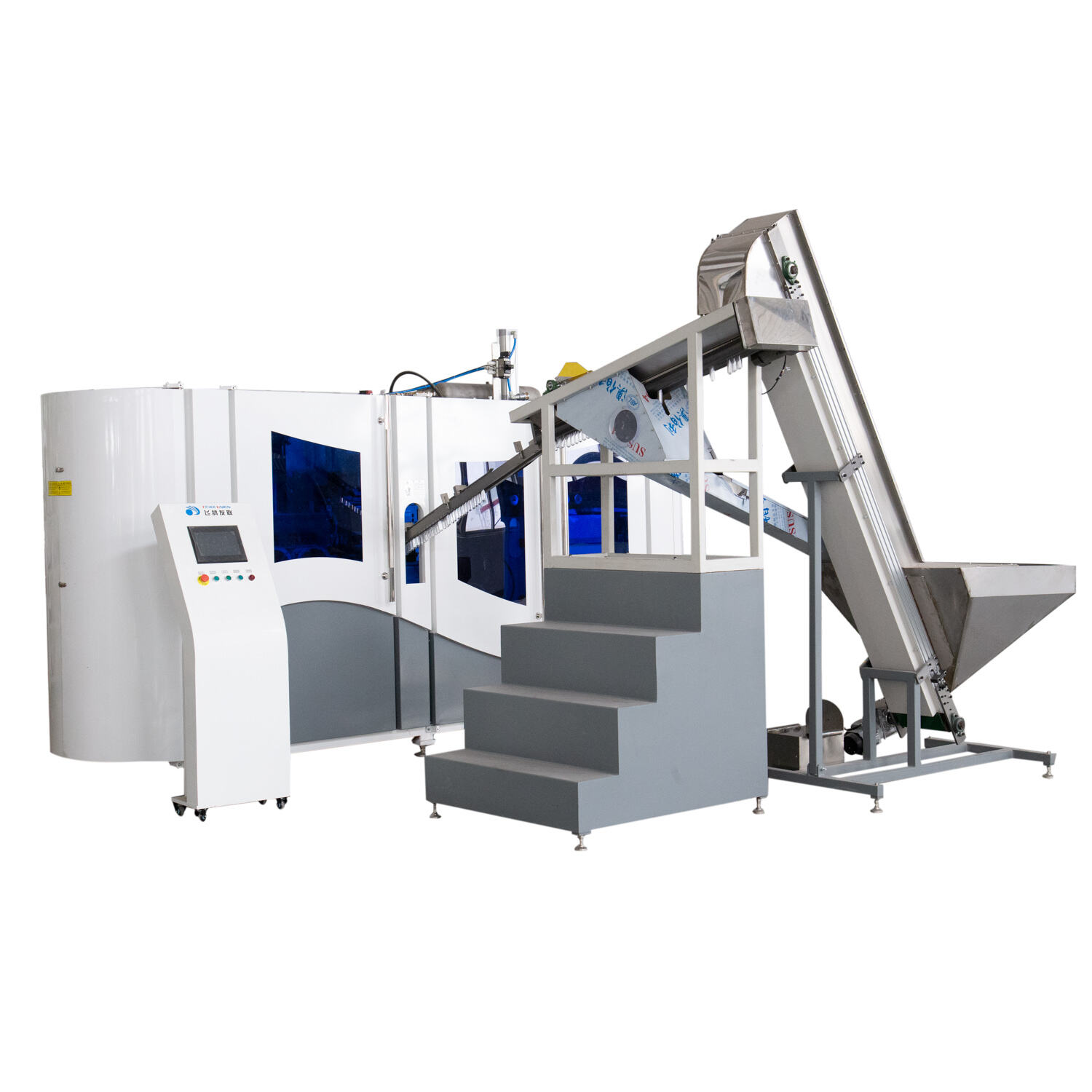

All those who are planning to invest in food processing as well as plastics need to know the exact working of HDPE Blow Moulding Machines. These machines melt HDPE plastic pellets. Then the option is actually injected in to a cylinder where it sets and then pushed into lead through sky tension. The plastic then takes the shape of that mould; when it has cooled and hardened, this is also cut down to size. HDPE blow moulding machineautomatic HDPlantic bottlemakerThere are numerous components which could be produced the usage of precise hdpe/ldpe metals and additionally they'll fluctuated from little container covers, cans to Resolve-box rather huge warmer tanks.

To sum up, HDPE blow molding machines have changed the view of plastic and it has facilitated manufacturers to produce sustainable quality products. Knowing how these function and what benefits they provide will help us appreciate more of the fancy technology that goes beyond a piece of plastic-device.

sales representatives all hours of the day to provide fastest possible service. invite you contact us if have any queries about products. Patents and certification: Faygo Plast has 13 national patents. Among them are 8 invention patents. We are always hdpe blow moulding machineour products provide the latest technologies our customers. products have CE ISO certificates

FAYGO UNION GROUP made from 3 hdpe blow moulding machine. FAYGOBLOW a blow molding machine manufacturer PET, PE other materials. FAYGOBLOW has 5 patents covering inventions, eight patents utility models. FAYGO PET blow molding machine among fastest and most energy-efficient design worldwide. second manufacturing facility is FAYGOPLAST, which make plastic extrusion equipment. This includes the plastic pipe extruding line and extruding line for plastic profile. Particularly, FAYGOPLAST is able provide PPR, PE pipes at speeds that can reach that can reach 40m/s.

More output (doubled) Rotary perform continuous running instead of stepping step-by-step run more smoothly. Reduce Bad Bottle Rate. Only two heating boxes, with each head's distance the heating source decreased to 38.1mm, which can reduce 30% more hdpe blow moulding machinethan the conventional model, which is about 130000kwh electric power, so an entire year, based on 8 hours per day, could reduce 20000USD only heating power. More than 100+ countries choose to be partners and my company after service team.

FAYGO UNION GROUP now more than 500 customers spread across countries like UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. From Europe, America (Canada, Mexico, Brazil Venezuela, Chilly, etc.) and Saudi Arabia, Iran Syria, India, Thailand Indonesia Thailand Indonesia. Many customers coming from Africa as well as Asia. Our factory, which is located in Zhangjiagang City, has an area of 26650 square hdpe blow moulding machine. only takes around two hours driving to SHANGHAI International Airport.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy